Search

Quickly find the products you need.

- All

- Product management

- News

- Introduction

- Enterprise Departures

- Frequent questions

- Business video

- Company Atlas

Chin-Chin

Download:

Ingredients and Texture of Chin Chin:

The traditional ingredients for Chin Chin primarily include white flour. If corn flour is used instead of wheat flour, the texture of Chin Chin will be different because corn flour has very different properties from wheat flour. Corn flour does not contain gluten, which is the substance that solidifies during baking, allows air circulation, and causes rising. Gluten is what gives Chin Chin its hard and crispy texture, which is the preferred texture for most West Africans. While some recipes can substitute white flour with corn flour and other starches, it might not be easy to change the traditional texture for Chin Chin. Therefore, using corn flour instead of white flour may not yield the desired results.

Production line:

|

|

|

| Minimie Slitting Machine | Chin Chin Cutting Machine | Chin Chin Conveying Machine |

|

|

|

| Pre-Drying Machine | Pre-Drying Machine Pipeline | Frying Machine |

|

|

|

| Oil Removing Machine | Frying Machine Pipeline | Frying Heat Exchanger |

|

|

|

| Frying Machine Output | Cooling Machine | Cooling Machine Outlet |

|

|

|

| Packaging Of Chin Chin | Weighing System | Finished Product Conveyor |

|

|

|

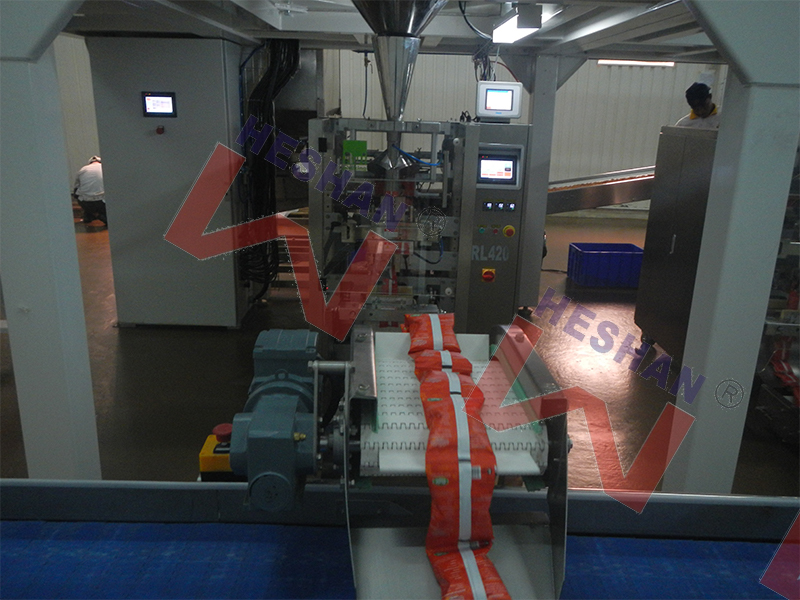

| Multi Head Weighing Machine | Finished Product Conveyor 1 | Mini Mie Packing Machine 1 |

|

||

| Packing Area Of Mini Mie |

Chin-chin Mixer Structure :

Mixer is in fact a double-arm mixer, which consists of equipment body, frame, mixing shaft, cylindrical or leaf-shape agitator, discharging door, water adding device, transmission as well as controlling part. All food contact surfaces such as the equipment body, discharging door, cylindrical agitator, the two shafts and so on are made of stainless steel. If it is angled leaf-shape agitator, such agitator is normally made of aluminum alloy and coated with PTFE. There are teeth scrapes on the agitator which helps with mixing the dough as well as cleaning the flour and dough that stick on the inside wall of the mixing chamber. The gap between the agitator and the chamber bottom is 5mm, while the agitator to the chamber sides is 10mm. The water adding device is installed at the back of the mixing chamber. Water pipe is sealed on both sides and connected from the middle with the quantitative tank. There are a row of equidistant holes at the pipe bottom with a deflection of 45 degree. The total area of all the holes is smaller than the sectional area of the pipe, so as to make sure the water flows fast and is spayed evenly between the two shafts. There are two types of discharging device: manual discharging device and electric discharging device. Manual discharging device mainly adopts the principle of rack-and-gear linear movement changing into connecting-rod arc movement, so as to control the discharging door. By replacing the manual part with the electric part, then comes the electric discharging device.

Working Principle of Chin-chin Mixer :

Double arm mixer has helix racks on its two shafts which go alternatively and continuously from the two sides, then downwards, then to the middle and then upwards. The two pairs of helical vanes on the two ends of the shafts keep stirring the Chin-chin dough, and at the same time keep transferring it to the middle. This mixing process brings convection motion and diffusion motion in between flour and water. Chin-chin dough is tumbled back and forth inside the mixing chamber. As its temperature goes up gradually, the Chin-chin dough turns from white flour into light-yellow bean dregs. After mixed for some time, the wheat flour is fully mixed with water and additives, and forms into an elastic, resilient, extensible and plastic dough.

Based on the position of agitator blades, mixer can be divided into tangent mixer and overlapping mixer.

Chin-chin Tangent Mixer :

Its two agitator blades are built apart on the common tangent. The two blades operate independently and without interfering with each other. The speeds of the two blades can be decided differently. It is like two single-arm mixers operating inside one same chamber.

Chin-chin Overlapping Mixer :

Its two agitator blades are built crosswise. As the blade moving trails are overlapping, their design, shape, motion path and moving speed must not interfere with the other. Normally, their moving speeds should be 1:2 or 1:1. If it is 1:2, the blade with faster speed will chase the blade with lower speed which will make the dough fully folded, stretched and kneaded.

Main Parameters for Chin-chin Double-arm Mixer :

See below Table 1

| Capacity/kg |

150-250 |

|

Rotating Speed of Agitator Blade / r/min |

78 |

|

Mixing Time/ min |

15 |

|

Power/ kw |

5.5-11 |

|

Dimensions(L X W X H)/(mmXmmXmm) |

2000X1000X1200 |

Chin-chin Upright Aging Machine :

Upright Aging Machine is also called Disk-type Aging Machine or Disk-type Feeder. Its transmission shaft is vertical with two mixing rods in different lengths. This design is characterized in that its rotating speed is slow and therefore good for the aging process. By comparison, Horizontal Feeder is more complex in design and causes many dough clumps during production which results in problems in feeding, while Upright Aging Machine is neat in design and requires small floor area. And it is also easier to clean.

(1)Structure of Chin-chin Disk-type Aging Machine

It mainly contains equipment body, mixing rod, discharging device, and transmission device.

Food contact surfaces are all made of stainless steel. Mixing rod is made of aluminum alloy or stainless steel (if it is made of aluminum alloy, it should be coated with PTFE). Mixing rod is arched in the middle. The feeder volume should not be too small and it should equal to one third of the Chin-chin line output. Feeder shape should be round and its height-to-diameter ratio (H/D) is 1/6. Rotating speed of the vane should be 2.5 to 5 r/min. Chin-chin dough should stay in the feeder long enough (preferably 30 minutes) so as to achieve aging effect.

The mixing rod rotates slowly and counterclockwise during operation. The disk is 250 to 300mm in height with diameter of 1000 to 1800 mm in diameter. The rotating speed of the main shaft is 5 to 8 r/min. This speed is reduced through primary gear transmission and then further reduced by the worm reduction box. The disk is without cover so that the heat is easily emitted. On the bottom of the disk while near the edge, there is a discharging hole which is adjusted by a flashboard. A safety head is installed above the discharging door. Underneath the safety head, there is a contact micro switch which is connected with the mixing motor. When the discharging door is obstructed and the block needs to be removed manually, workers have to open the safety head by hands. At this time, the micro switch will be disconnected and the mixing rod will stop working. This device can effectively avoid hands crushed by the mixing.

(2)Working Principle of Chin-chin Aging Machine

As the aging process requires a low-temperature and steady environment, the mixing rod retains at low rotary speed. And this not only ensures even feeding, but also helps to loosen the dough and keep it in an incompact state and in particles. The aging time is determined based on volume, the size of discharging door, the size of the flashboard and the rotary speed of the mixing rod. The dough from feeder will go into Compound Rolling Machine and this is the complete process of feeding. The dough from feeder is loosened and soft. Its staying time in the aging machine should be between 15 to 45 mins.

Chin-chin Compound Rolling Machine :

Compound rolling is a process that rolls the aged dough through multiple rollers and make it into the required dough sheet. Compound rolling is also called pressing. The traditional way of Chin-chin making is by hand. The dough is kneaded by hand and rolled over and over again by a rolling pin. Gradually, the dough is pressed into a dough sheet with certain thickness. Machine rolling is developed based on this traditional way. The dough goes through multiple sets of counter-rotating rollers and forms into a dough sheet. By putting pressure on the dough, scattered wet gluten in the dough will be connected together. The wet gluten network surrounds starch particles and spreads evenly on the dough. This improves the processability and the cooking properties of the dough. Compound rolling is the central processing link in the whole Chin-chin line and greatly affects the quality of final Chin-chin products.

Chin-chin Dehydrating and Frying Machine:

(1)Basic Principle and Requirements of Chin-chin Dehydrating and Frying

Dehydrating and frying is a process that fries the Chin-chin squares in an automatic fryer. In the fryer pan with high-temperature oil, Chin-chin squares’ temperature goes up high shortly and water contained in Chin-chin evaporates fast. That makes the Chin-chin squares a porous structure and increases its texture. Dehydration helps to reduce the water content in Chin-chin and hence it is better for storage.

Requirements of Frying: even frying, unanimous color, no over-frying, less oil content and other quality requirements.

Chin-chin Cooling Machine:

Basic Principle of Cooling

After frying, Chin-chin has a comparatively high temperature. Its temperature still remains from 80 to 100℃. When Chin-chin comes out from the hot-air dryer, its temperature is around 50 to 60℃. If Chin-chin is packed in bags in such temperature without cooling down, its shelf life would be very short. What is more, if cooling is not conducted the right way according to requirements, the steam will be generated inside the bag and Chin-chin will get mildewed. So it is necessary to let Chin-chin go through the cooling process. There are two ways of cooling: natural cooling and forced cooling.

Next

Get in touch with us

Get in touch with our team in a timely manner and would be happy to assist you