Search

Quickly find the products you need.

- All

- Product management

- News

- Introduction

- Enterprise Departures

- Frequent questions

- Business video

- Company Atlas

Seasoned Peanut Roasting Production Line

Download:

Description:

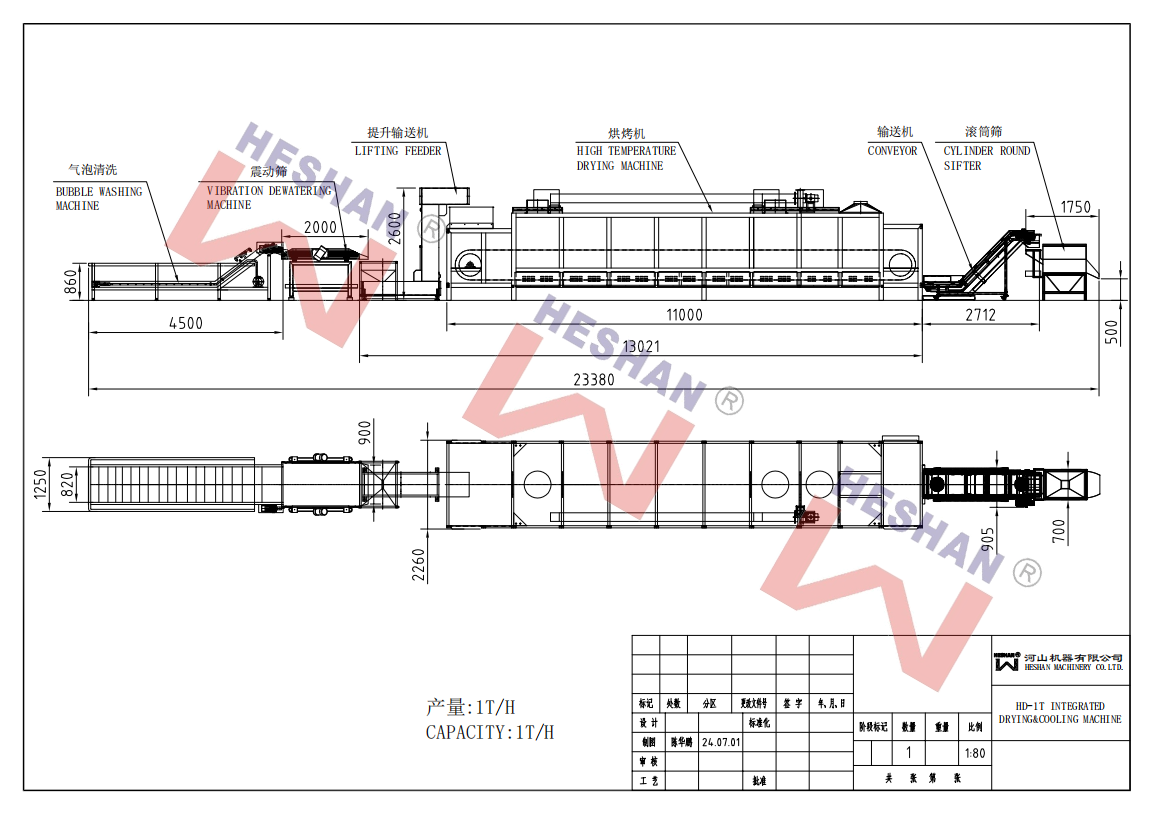

The Heshan seasoned peanut roasting production line uses a process of spraying seasoning liquid and coating powder to combine syrup, peanuts, and mixed powder. This is followed by a continuous roasting process, which matures the peanut and reduces their moisture content to around 3%, resulting in crispy and tasty seasoned peanut. The production line is fully automated, ensuring high production efficiency, uniform coating, stable roasting temperature, and finished products that meet European and American standards. The roasting production line is CE certified.

Specification:

| Kinds | Seasoned Peanut Roasting Production Line | ||||||

| Model | CP-200 | CP-400 | CP600 | CP-800 | CP-1000 | CP-1200 | CP-1500 |

| Capacity kg/Hour |

200 | 400 | 600 | 800 | 1000 | 1200 | 1500 |

| Driving Power | 30KW-70KW(Excluding Electric Heating Power) | ||||||

| Heating Source | Electricity, Natural Gas, Light Oil, etc | ||||||

| Operator/shift | 2-3 | ||||||

| Overall Dimension | L(30M-60M )× W(3M-3.5M) × H4M | ||||||

Production line:

|

|

|

| Z-Type Peanut Hoist | Peanut Distributor | Dryer Inlet |

|

|

|

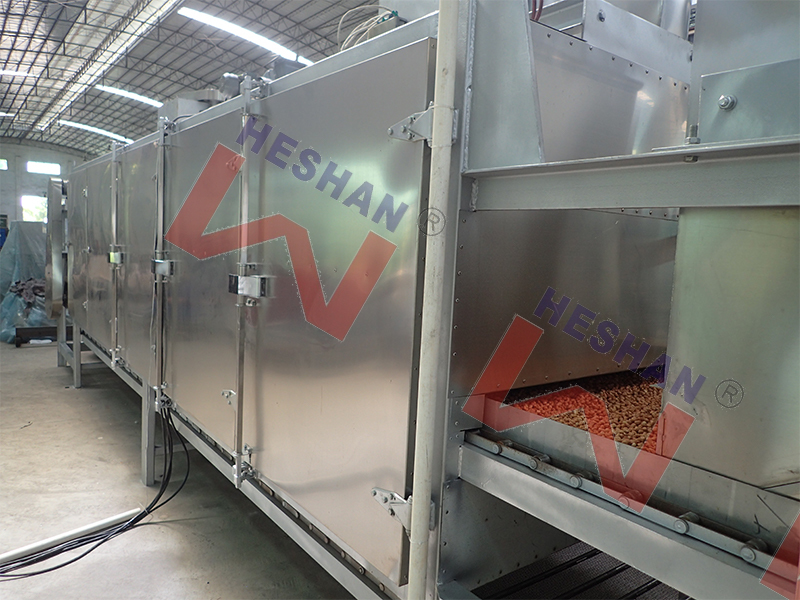

| Dryer Panorama | Dryer Outlet | Electric Nut Dryer |

|

|

|

| Continuous peanut roasting production line | Gas Peanut Roasting Machine | Electric Continuous Roasting Machine |

|

|

|

| Coated Peanut Roasting Machine | Nut Roasting Machine | Peanuts After Drying |

|

||

| Peanut Sorting Machine |

Peanut Roasting Production Line Flowchart:

Process:

1. Raw materials

2. Auxiliary materials

3. Coating

4. Initial seasoning

5. Conveying

6. Roasting

7. Secondary seasoning

8. Finished product

The peanut roasting machine is a new type of multifunctional roasting (drying) machine for peanuts, grains, and nuts. Its advantages include a high degree of automation, automatic temperature regulation, and multiple heating methods, such as electric heating and gas heating. By using a circulating fan to exchange heat, it achieves strong airflow roasting, enhancing both roasting efficiency and quality. The machine has a cooling zone at the end, allowing for integrated roasting and cooling in a compact structure. It can process various granular foods, including five-spice peanuts, milky peanuts, sesame-coated peanuts, almonds, cashews, and buckwheat.

Get in touch with us

Get in touch with our team in a timely manner and would be happy to assist you