New progress and existing problems in the production of stick rice vermicelli

Stick rice vermicelli is a major rice products in China, deeply loved by people. But due to the complicated production process, it is mainly produced in small factory or family workshops, caused the development on this industry is restricted and is still in a labor-intensive state. In these few years, some large enterprises have brought in new equipment for production, especially in the labor-intensive stations such as continuous mixing, vermicelli extruding, resteaming, vermicelli loosing process and etc., the production has been more and more mechanically, continuously and automatically. With the emergence of production line, the stick rice vermicelli industry will enter a new period of development, leading an improvement on equipment. We believe that the following points should be attention during the innovation of vermicelli equipment .

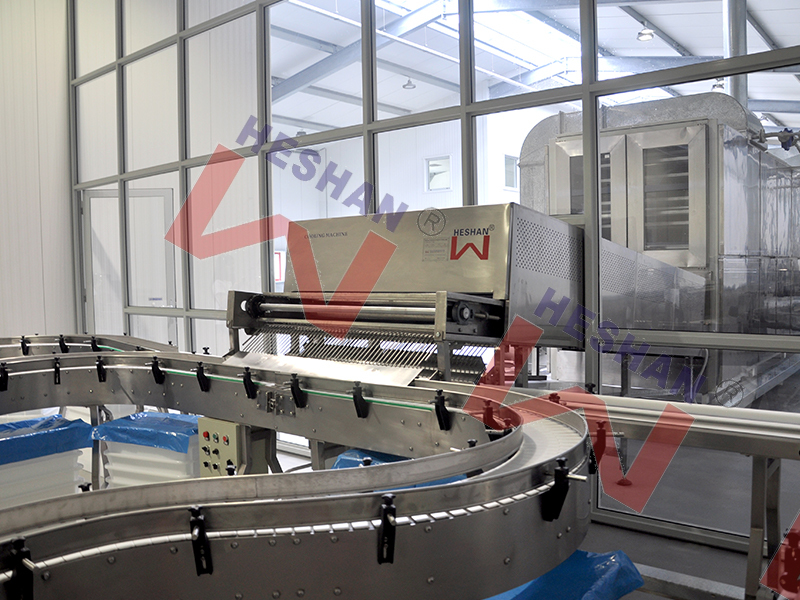

1.Reducing labor force and increasing productivity

The use of continuous mixers in the production of stick rice vermicelli instead of manual feeding, and the matching ratio of various materials and the allocation of water content can be adjusted at any time. With the using of rectangular vermicelli extruding template, the extruding mouth has been improved to much longer, will helps to cool down the vermicelli easier, and no need to move and hang the vermicelli evenly to trolleys manually. Under the using of aging and drying conveyor, it is no to transport vermicelli by trolleys. With bridge type steaming machine’s using instead of cabinet type steaming machine, it is no need to push or move vermicelli by hands, the potential safety hazards of steaming cabinet under pressure can be eliminated. The carding machine has completely replace human labor, no need for manual rubbing, kneading, combing and other operations on vermicelli. However, it still takes a lot of man power to solve the vermicelli arranging and packaging because the vermicelli is not 100% separated. After drying, the end part often slightly curved and effect the next step’s using of packing machine. Therefore, it need to make further study on carding machine and drying machine.

When the vermicelli extruding machine working unevenly, it might cause one end of vermicelli are not neat and in order after hanging on bars, when combing the vermicelli, one end has left the comb while the other end uses to be tear off because of the unneat part, and affect the yield rate and low down the whole productivity.

2.The slurry rate

Many stick rice vermicelli plants use to set the slurry rate of their products below 8%, but in fact, most of the products are exceeded, and some even reach 15%. Some people believe that the paste soup of stick rice vermicelli is a kind of characteristic of it, the slurry rate reflects the degree of gelatinization and aging of the product.

The stick rice vermicelli are friction ripening, the moisture content of material becomes the key factor affecting gelatinization when entering the self-ripening machine.

The emergence of continuous mixer has made a big step forward in continuous production process, it is a breakthrough, but there are some defects on current mixing method, which affect the gelatinization of starch. The main reason is that the water content of corn starch and rice flour entering the mixer is over 15% point, it is difficult to ensure the corn starch absorbs enough water when entering the continuous mixer for mixing and impossible to ensure it can be fully gelatinized with corn starch, which ultimately affects the slurry rate of product. If the mixing method is changed to mix corn starch and water first, increasing mixing time for water with corn starch and raise the water content of rice flour before entering continuous mixing, it will be have better effect rather then adding directly, the rice starch and corn starch can be fully gelatinized, and slurry rate of product can be reduced.

Water content has a great influence on starch gelatinization, some data mention that the starch with a water content of less than 30% can not achieve complete gelatinization, and the water content of the existing process into the material of the self-ripening machine is about 33%, and it is necessary to study the self-ripening machine that adapts to higher water content. Re-steaming can improve the gelatinization of the vermicelli and make it more smooth and glossy. However, re-steaming is easy to stick together, increasing the difficulty of combing vermicelli. When setting the resteaming parameters, some take 75 °C for 2.5 minutes, some use 90 °C for 1.5 minutes, etc. In order to loose vermicelli easily, take a short heating time or slightly lower heating temperature, do not let the temperature of the vermicelli rise too high, are considered to be easy to make drawing after resteaming. In the new design, it is necessary to enter in-depth exploration and research on the self-ripening machine and the self-ripening process, so that it can not only improve the gelatinization degree of vermicelli, but also not affect the operation of the equipment due to viscosity, nor will it increase the drawing rate of the product, and at the same time, it should also develop to large-scale to meet the needs of the development of production.

Research to improve the performance of the carder and adapt to the combing ability of the vermicelli after deepening the resteaming degree.

3.The qualified finish product rate

It is a common phenomenon that the qualified finish product rate of stick rice vermicelli is relatively low, because the cutting of stick rice vermicelli affects a lot.

In production, it uses to hang the stick rice vermicelli on bars for facilitate transportation. The bent part of the hanging place about 60mm long cannot be made into qualified product. While the tail part about 110mm long is not neat and curved, it is also be listed outside of qualified product. For cutting vermicelli, it is cut with a saw blade, each incision is 2.5mm. If each hanging vermicelli takes 5 sections of qualified product, 200mm long, and the lifting height of vermicelli before cutting off is 60 + 110 + 200 * 5 + 2.5 * 6 = 1185mm, due to the influence of drying, the vermicelli are not completely straight, especially near the tail end section, if this section can not become qualified, the qualify rate will be low. There is also the effect of sticky vermicelli, the sticky rate after cutting is 5%, then the qualified rate is only (200*4)/1185*(1-5%)=64.1%. If 6 sections are taken from each hanging vermicelli, there are 5 sections into qualified products, 200mm long, and the lifting height of the vermicelli before cutting is 60 + 110 + 200 * 6 + 2.5 * 7 = 1388mm, and the qualify rate is (200 * 5) / 1387.5 * (1-5%) = 68.5%. For example, 7 sections of each hanging powder are taken, 6 sections are qualified, 200mm long, and the hoisting height of the vermicelli before cutting is 60 + 110 + 200 * 7 + 2.5 * 8 = 1590mm, and the qualify rate is (200 * 6) / 1590 * (1-5%) = 71.7%. It can be seen that the hanging length of vermicelli is increased, more cutting sections is, the combing effect is improved, and the straightness of the vermicelli after the dryer is better, which will improve the qualified output of the product. If 6 sections are taken from each hanging powder, there are 6 sections into qualify products, 200mm long, the hoisting height of the vermicelli before cutting is 60 + 110 + 200 * 6 + 2.5 * 7 = 1388mm, the sticky rate after cutting is 2%, and the qualify rate is (200 * 6) / 1387.5 * (1-2%) = 84.5%, which is an increase of 20 percentage points. For example, 7 sections of each hanging powder are taken, 7 sections are qualified, 200mm long, and the lifting height of the vermicelli before cutting is 60 + 110 + 200 * 7 + 2.5 * 8 = 1590mm, and the qualify rate is (200 * 7) / 1590 * (1-2%) = 86.3%, an increase of 22 percentage points.

4.The energy consumption of products is relatively high, especially for refining raw materials, which is a problem in all rice vermicelli production.

Regardless of whether the dry crushing method or the refining filter method is used in the production of rice flour, the raw materials are refined in gelatinization, so as to make the materials easier to gelatinize and more fully gelatinized. For example, a manufacturer adopts a dry method, and the equipment configuration adopts a micro pulverizer. The main crushing motor is 45kw, the grading motor is 7.5kw, the feeding motor is 0.55kw, the airflow conveying motor is 18.5kw, and the motor of the air turbine is 1.5kw, totaling 73kw, crushing rice 600kg per hour, crushing 10kg of rice to be equipped with 1.2kw power. And the equipment is noisy when running, and it is not easy to clean the inside of the equipment and in the pipeline. The methods and equipment for refining raw materials need to be further explored and studied.

5.The equipment is huge and covers a large area

Stick rice vermicelli do need for secondary aging. The first aging takes 6-8 hours, and the second aging takes 3-4 hours. Since the water content of vermicelli is only about 33%, a slight decrease in the water content will seriously affect the aging effect. In order to maintain the water content of vermicelli and the aging environment, manufacturers often use the method of putting steam into the aging machine. With putting in the steam, the moisture content in the aging machine is guaranteed and the moisture in vermicelli is not easy to lose, but the vermicelli is aged under over 40℃, and even sometimes over 60-70℃, which is not the best temperature for aging, so it must to extend the aging time to achieve the aging effect, and the result is that the equipment is relatively large. If the aging machine can not only maintain the humidity and temperature suitable for starch aging, but also maintain the water content of vermicelli, will ensure the aging quality of vermicelli well and can shorten the aging time, the equipment will be lightweight.

The drying time of stick rice vermicelli is really long, some up to 12 hours. Now, the wet rice flour has a water content of 60%, and it can be dried to less than 13% after 60 mins, the transformation potential of dryer for stick rice vermicelli is great, and the volume of equipment can be shortened a lot.

The production line of stick rice vermicelli has been formed, and has made a great progress, but it still needs to spend great effort to research and explore to become a modern equipment, low energy consumption and high productivity equipment.

Recommended